Already Severn Trent’s second largest facility, Wanlip Sewage Treatment Works in Leicestershire is undergoing a five-year, £150 million upgrade.

While it may seem logical that such a facility would have sufficient provision for toilets, the reality is quite different when an additional labour force is brought in for the upgrade. As on any other construction site, toilets and cabins must be provided across the site and the effluent from these cabins must be handled in just the same way.

With Water Authority spending of taxpayers’ money currently in the spotlight, Severn Trent was determined to reduce the cost of the upgrades wherever possible.

Site toilets traditionally feature a tank that sits underneath the cabin to contain the effluent from the toilets. As these effluent tanks have a limited capacity, they require frequent emptying to keep the toilets functioning properly. The costs of regular effluent tanker visits can be a significant contributor to the operational costs of a construction project, and the Wanlip site was no exception.

If a toilet cabin can be sited directly above a gravity drain, then effluent waste can be directed straight into the drain, but the nearest gravity drains to toilet cabins at Wanlip were nearly 1,000 metres away.

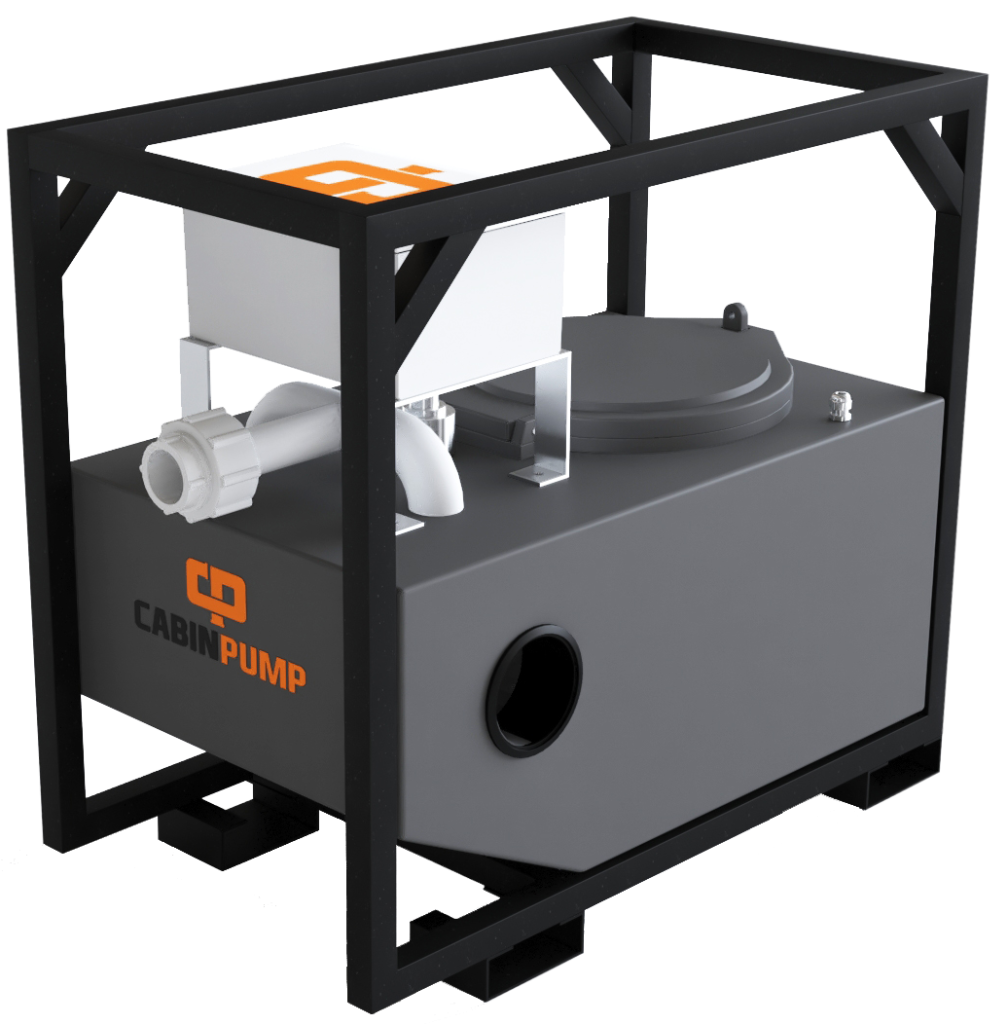

CABINPUMP Ultra proved to be the perfect solution for this situation. Featuring a PowerPack bolt-on to increase the pumping distance, this system macerates effluent into a sludge and pumps this easily across larger distances to a gravity drain.

As work at Wanlip continues to progress, the upgrade teams are now equipped with toilet facilities that are light on the public pocket. And while the usual CABINPUMP benefit of eradicating the unpleasant smells of a traditional under-cabin effluent tank may be wasted at Wanlip, the reduction of carbon emissions as a result of eliminating tanker collections will undoubtedly make the air a little sweeter.

Download the CABINPUMP Ultra specification sheet here